Heating Equipment Management System

The modern heating equipment market strives to meet the increasingly higher standards of efficiency, safety, and ease of operation. Centralized and remote control of boilers, pumps, ventilation units, and other devices has become especially relevant for industrial enterprises, commercial facilities, and residences. IoT solutions enable remote control and monitoring of energy consumption and timely response to potential malfunctions or emergencies.

Request

The client’s company sells boilers, ventilation systems, pumping equipment, and other solutions to private consumers and commercial enterprises. The equipment comes with a control and monitoring system designed by one of the company’s suppliers. However, this solution can’t meet the client’s business requirements. He wanted to replace it with a similar management system better adapted to his needs. That’s why he contacted Integra Sources.

Our job was to develop a solution that allows for remote control of equipment (boilers, ventilation systems, underfloor heating, and pumps) via the eBus. The project had the following requirements:

- The client requested not a copy of the reference device but an improved analog. Our team had to analyze and eliminate all the drawbacks of the original system. The new solution needed to be more flexible and better tailored to the client's business requirements.

- The system had to be developed in such a way that it could be easily adapted to work with new equipment models in the future.

- The metrics in the user application needed to be externally configurable. This would allow the client to configure the app for any equipment, both currently supplied by the company and new models.

- The client also asked Integra Sources to manufacture the test batch of the devices (gateways for connecting equipment to the internet).

Solution

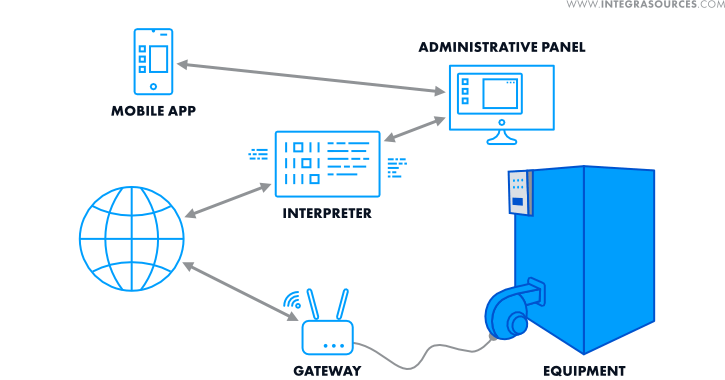

The solution we developed includes the following key components:

- Gateway that provides data and command transmission between the equipment and the internet.

- Interpreter—a microservice that translates data into a format understandable by the equipment and other components of the system.

- Mobile application designed for controlling the equipment and monitoring its status.

- Administrative panel—a server application that stores the data necessary for the system’s operation and serves as an interface for configuring the mobile application and other system components.

Gateway

We decided to move the main system logic to the server and significantly simplify the device itself. The gateway we designed transmits signals between the equipment and the internet and also processes special commands for interaction with the eBus. The device connects to boilers or other equipment via the eBus and can access the internet via Ethernet or Wi-Fi to exchange data with the server using the MQTT protocol.

At the initial stage, our engineer assembled a prototype of the future device using a PCB originally developed for a smart home system in another project. It is based on a similar microcontroller and has the necessary network interfaces (Ethernet and Wi-Fi), making it a perfect fit for this role. The assembled prototype allowed the team to study the specifics of the eBus and begin developing the embedded software even before the reference device arrived.

Interpreter

When transmitted from the equipment to the application or administrative panel and back, the data needed to be converted into a format understandable by each component of the system. To achieve this, we developed a standalone microservice—a small autonomous system element that interacts with other parts via interfaces. A microservice architecture divides the software into independent pieces. Each of them can be developed, tested, updated, and scaled separately. In addition to data conversion, the interpreter also schedules packet transmissions, generates and sends messages, reads and updates data on schedule, and performs other important functions.

Administrative Panel

We also developed a server application that allows users to:

- Manage the database;

- Configure parameters and templates for the equipment;

- Set up the display of equipment metrics in the mobile app;

- Support technical requests and collect technical information;

- Manage user subscriptions to additional services;

- Control user access to various system components;

- Automatically collect statistics from client equipment;

- Track equipment failures;

- Support communication between users, service centers, and technical support;

- Generate various technical reports.

Mobile Application

The team developed a smartphone application that allows the customer’s clients to remotely control the equipment and monitor its status in real time. The app users can register their equipment and its configuration in the server database, view the status of devices, adjust their operation, and receive various notifications related to their account.

Major Issues Resolved

Solution Versatility

Although the system was designed to work with devices via eBus, the client requested that the system be easily adaptable to new equipment models and other communication protocols. We implemented this feature in the administrative panel, most notably in the database scheme. On top of that, the team designed the interpreter to be able to handle unknown message types.

Application Flexibility

The customer offers a wide range of heating equipment, and all its parameters need to be displayed in the user application. Our task was to design the solution so that the client’s staff could independently configure what metrics to display for each device model. This required significant work, but we achieved the necessary flexibility. New equipment can be added to the list in the administrative panel. After that, the staff can select what parameters to display in the mobile app and where exactly. Thus, the client will not need to update the app for each new model—simply configuring the program will be enough.

Data Transmission to Equipment

eBUS is a digital control bus designed for data exchange between heating equipment and control devices. It is used in products from numerous manufacturers and allows combining up to 25 master and 228 slave devices into a single network. It was our first time working with this technology, so we had to study it carefully.

Extra research was required to understand what responses different equipment sends over eBus, as such information could not be found in their documentation.

Mobile Application Design

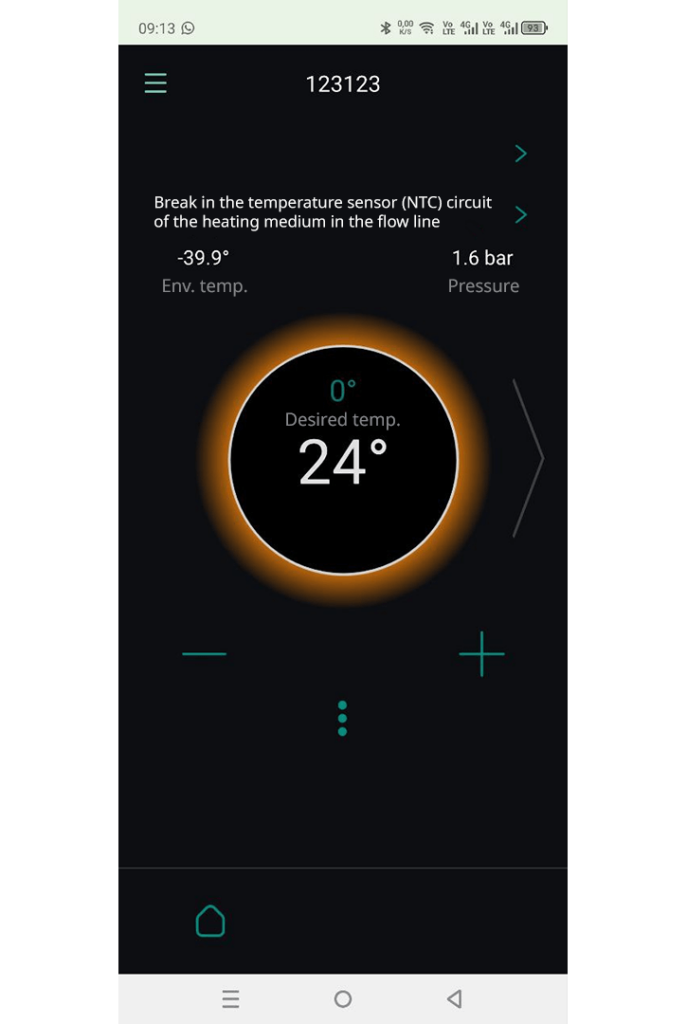

The customer requested that we pay due attention not only to the functionality of the system but also to the aesthetics of its components, particularly to the main screen of the mobile application. However, design is a creative process that requires many iterations and approvals. Therefore, our developer contacted the client to hear out their suggestions and discuss ambiguous aspects of the design. Then, the developer prepared templates based on the client’s requests, and they reviewed each proposed option together. The client explained what they wanted, and the developer adjusted the corresponding parameters to immediately see the results.

In the end, the customer chose the following design: the color of the circle reflects the difference between two parameters inside it.

This allows users to quickly understand the equipment’s status. For example, the image above displays the current (24℃) and desired (0℃) temperatures in the boiler, and the orange color indicates that the boiler is still cooling down.

Scope of Work

- Gateway schematics and PCB design.

- Embedded software development for the gateway.

- Developing the administrative panel and creating the database structure.

- Interpreter microservice development.

- Mobile user application development.

- Manufacturing a test batch of gateways.

Technologies

- Altium Designer for creating the schematics and PCB design.

- MCU — ESP32.

- Firmware for the gateway — C++.

- The administrative panel was developed in Java and XML using the Jmix framework.

- Additional microservices were developed in Go using Visual Studio Code.

- Interpreter — Go.

- The mobile application was developed in C/C++ using the Qt framework for Android and iOS operating systems.

Result

- The client received an improved analog of an existing remote control and monitoring system for heating equipment.

- At the customer’s request, Integra Sources enhanced the outdated functionality of the reference solution and eliminated its drawbacks.

- The system was designed to be flexible and versatile. It can be quickly adapted to new equipment models without significant software modification.

- The project is now nearing completion. We have manufactured 30 test samples of the gateway, which are undergoing tests in real operating conditions. The team is addressing any issues and is ready to provide the client with technical support when the system is launched.

Integra Sources’ expertise and the client’s involvement in the project made it possible to create a highly customized and scalable analog of an existing solution. Its flexibility and versatility will allow the customer’s business to secure a strong position in the market. As for our team, we gained valuable experience working on a large-scale project that involved a number of non-standard solutions.

You might also like...

Firmware Development for Augmented Reality Glasses

The team improved the customer’s firmware for augmented reality glasses by developing drivers for the displays, accelerometer, and gyroscope of the device.

LEARN MORE

Software for EEG System

The Integra Sources team developed energy-efficient embedded software and an SDK for a medical EEG system. We delivered robust data transfer and storage, implemented multitasking on FreeRTOS, and improved connection security.

LEARN MORE