This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

Guide to Consumer Electronics Certification in the US & EU: Requirements to Consider Before Mass Production

Timur Yuldashev

IT Writer, PhD in Philological Sciences

Andrey Solovev

Chief Technology Officer, PhD in Physics and Mathematics

- What Products Require Certification?

- Common Consumer Electronics Certification Types

- How Much do Certifications Cost?

- Common Testing Methods Required for Consumer Electronics Certification

- General Electronics Certification Steps

- Tips on Consumer Electronics Certification

- How we Manage Certification Challenges

- Conclusion

- What Products Require Certification?

- Common Consumer Electronics Certification Types

- FCC Certification Requirements

- Conformité Européenne (CE) Requirements

- UL Certification Requirements

- Restriction of Hazardous Substances (RoHS)

- Registration, Evaluation, Authorization and Restriction of Chemicals (REACH)

- How Much do Certifications Cost?

- Common Testing Methods Required for Consumer Electronics Certification

- CE RED Testing

- Electromagnetic Compatibility (EMC) Testing

- Electrostatic Discharge (ESD) Immunity Testing

- General Electronics Certification Steps

- Tips on Consumer Electronics Certification

- How we Manage Certification Challenges

- Conclusion

We are launching a publication series dedicated to electronics certification and testing. What are the requirements for a valid electronics certification? What are the most common consumer electronics certification types in the US and Europe, and how much do they cost? In this article, we will answer these and other questions.

- What Products Require Certification?

- Common Consumer Electronics Certification Types

- FCC Certification Requirements

- Conformité Européenne (CE) Requirements

- UL Certification Requirements

- Restriction of Hazardous Substances (RoHS)

- Registration, Evaluation, Authorization and Restriction of Chemicals (REACH)

- How Much do Certifications Cost?

- Common Testing Methods Required for Consumer Electronics Certification

- CE RED Testing

- Electromagnetic Compatibility (EMC) Testing

- Electrostatic Discharge (ESD) Immunity Testing

- General Electronics Certification Steps

- Tips on Consumer Electronics Certification

- How we Manage Certification Challenges

- Conclusion

Only certified electric devices and consumer hardware are allowed to be imported and sold. Countries impose various requirements related to health protection, environmental safety, and, in the case of electronics, their ability to interfere with other devices and wireless communication.

It may seem that a developer shouldn’t be concerned with product certifications before mass production. But since hardware certification takes place at the last step, if the product fails to meet the requirements, the developer will have to redesign it and postpone the production launch. For this reason, it’s important to know about the existing consumer electronics certifications and keep these requirements in mind when designing the concept of a new product.

If the task is outsourced to another company, it is crucial to choose a team with expertise, not only in electronics development but also in consumer electronics certification. That’s why our team pays due attention to the product certification in the US and other countries when offering electronic design services. When developing power electronics, embedded hardware, or a PCB design for manufacturing and assembly (DFMA), we always take into account the requirements and standards applied to new technologies.

In this article, we’ll cover the common electronics certifications required to manufacture or sell goods in the United States and Europe, what product types need to be certified, and how much it will cost you.

What Products Require Certification?

When it comes to electronics certification (often called “electrical certifications”), this category of goods can be divided into two types: incidental and unintentional radiators which are not designed to generate RF waves but do so nevertheless (electrical power lines, electric motors, transformers, computers) and intentional radiators that emit, transmit, and receive radio frequency electromagnetic radiation intentionally, as their primary function (cellphones, wireless microphones, walkie-talkies).

While the requirements for incidental and unintentional radiators can be less strict in some countries (for example, FCC certification), testing and certifying intentional radiators is almost always mandatory.

As a hardware development company, we often create consumer product prototypes that emit and/or receive radiofrequency waves, such as IoT devices and systems, systems that use GPS tracking, audio and video transmitters, wireless webcams, wearables with wireless technologies, unmanned aerial vehicles, remote control systems, etc. As a rule, all such devices must be certified in both the US and the EU.

These are examples of electrical devices that commonly must be certified:

Companies that want to sell electronics in the US and EU should know about the following list of “electrical certifications”.

Common Consumer Electronics Certification Types

FCC Certification Requirements

The Federal Communications Commission is an independent US government agency responsible for making sure electrical goods don’t interfere with wireless communication because of the RF emissions they produce. The FCC falls under the 15th section of title 47 of the Code of Federal Regulations, which requires that all electronics items that oscillate at 9 kHz or higher must be tested and certified to be manufactured and/or sold in the United States.

How to get FCC certification

The FCC product certification process depends on the product type. Unintentional radiators require a Supplier’s Declaration of Conformity (SDoC) to enter the US market. An SDoC can be self-issued, which means it’s enough to support the declaration with corresponding test reports from any credible testing lab. However, note that the responsible party issuing an SDoC must be located in the United States. Otherwise, companies will need to hire a US representative to issue the SDoC.

FCC requirements for electronics that intentionally radiate RF waves are stricter. Such goods must go through the full FCC certification process, which cannot be self-issued. Companies must hire an FCC-accredited laboratory to carry out the required tests, and only FCC-recognized telecommunication certification bodies (TCBs) have the right to draft the certificate.

Conformité Européenne (CE) Requirements

Conformité Européenne (CE) is the health, safety, and environmental protection standard of the European Union. It is mandatory for goods manufactured, imported, or sold in the European Economic Area. If you compare FCC vs CE requirements, you will see that they are very similar.

Certain directives require new products intended for the EU market to be tested and certified by conformity assessment bodies (also called notified bodies in Europe). For example, certifying medical, protective, and pressure equipment will require one of them. But if the corresponding directive doesn’t require an NB, then the manufacturer can carry out the tests using their in-house facilities.

To find a notified body for conformity assessment, companies can use the NANDO database. Most of them are located in Europe, but there are a few operating in Canada and the US.

UL Certification Requirements

Underwriters Laboratories is a certification company founded in 1894. Nowadays, it tests and certifies products, as well as sets standards for various industries. Its primary objective is to ensure new goods are safe to use, meaning they will not start a fire or explode, for example.

Strictly speaking, UL certification is not mandatory in the US. However, manufacturers should understand that UL is an internationally recognized symbol of safety and reliability. In other words, if you try offering a new product that doesn’t comply with any UL regulation, most retailers will simply refuse to take it. For example, Amazon requires UL testing for certain categories of products. Also, note that UL listing requirements vary by state.

How to get UL certified

To get UL certification, companies must contact one of UL’s official laboratories and offices. You can do it by finding the nearest facility on the list and contacting it directly. UL has labs all around the globe. Alternatively, companies can request a quotation on the UL website, in the Contact Us section.

Restriction of Hazardous Substances (RoHS)

RoHS certification is required in the European Union as well as the State of California. It verifies that electrical and electronic equipment does not contain hazardous materials in quantities exceeding the established threshold.

Unlike other mandatory certification types, RoHS certification can be self-issued by the manufacturer or importer of the product, as long as the company has the necessary equipment to conduct the tests. In most cases, one will need to use X-Ray Fluorescence Spectroscopy technology.

Alternatively, businesses can hire a third-party laboratory that can carry out the test for them.

Registration, Evaluation, Authorization and Restriction of Chemicals (REACH)

REACH is a European Union regulation applied to potentially dangerous substances that may be present in consumer products sold in the EU. Similar to RoHS, the regulation’s objective is to ensure products contain hazardous materials in quantities that do not exceed the set limits.

The range of consumer goods that need to pass REACH testing is very wide and includes clothes, jewelry, furniture, kitchen products, goods for pets, etc. Electronics and PCBs also require REACH testing, as electronic components contain hazardous chemicals in small quantities.

Companies can hire third-party laboratories and send them samples to conduct the required tests. The test reports can be requested by EU national market surveillance authorities if they decide to carry out an inspection.

How Much do Certifications Cost?

There is no straight answer to this question, as UL, CE, FCC, RoHS, and REACH vary in prices and complexity. Generally speaking, the more tests required, the more one has to pay.

FCC certification cost

FCC compliance testing cost depends on whether the product requires an SDoC or full certification. The average price for an SDoC is $2,500-5,000, while the price for full FCC product certification starts at $10,000.

CE certification cost

If a company can test the product with their own facilities, the final cost may be as low as $300. Otherwise, companies should expect to spend about $5,000 and more.

UL certification cost

The average UL testing cost is about $5,000-15,000 per product. Companies can also hire a consultant from UL who would guide the team during the development process to reduce the electrical Underwriters certificate cost.

RoHS certification cost

If you don’t have the necessary equipment to carry out the tests in-house, expect to pay third-party laboratories about $1,000 per product.

REACH testing cost

The cost of REACH testing depends on the number of substances you need to check. While every single test can cost between $20 and $100, the total price can rise to several hundred dollars if the product is made of different materials.

Remember that if a product fails the tests, companies will have to take another test after making the required changes. That’s why it’s important to design electronics with these regulations in mind.

Common Testing Methods Required for Consumer Electronics Certification

CE RED Testing

The Radio Equipment Directive (RED) is the European Union’s standard regulating electrical and electronic equipment that intentionally emits or receives radio waves. Technically, RED is not a certification type but rather a test. However, if your product is regulated by this directive, passing the RED test will allow you to obtain CE certification. RED testing is commonly required for televisions, smartphones, IoT, Bluetooth, Wi-Fi and short-range devices.

Electromagnetic Compatibility (EMC) Testing

EMC is another common test that developers need to pass in order to enter most markets. EMC refers to the ability of an electrical device to function properly without causing electromagnetic interference effects on other equipment. The test also proves that the device is able to withstand common hazards, including electrical fast transients, electrostatic discharges, and lightning strikes.

Electrostatic Discharge (ESD) Immunity Testing

The ESD immunity test is a type of EMC test that is required to make sure your product can withstand electrostatic discharge events, since even a slight ESD can damage electrostatic discharge can damage sensitive electronic components. The test uses the application of discharges to the device through contact or by air. ESD is usually carried out as a part of larger EMC testing.

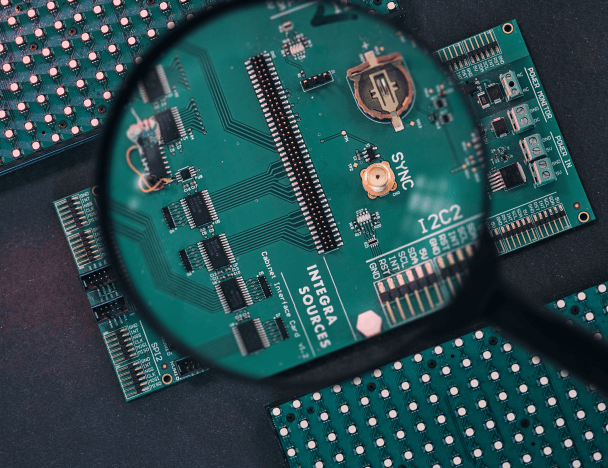

Companies that develop electronic devices usually perform these and other tests in-house during the development process and before applying for certification. It helps them ensure that the future prototype will not require significant changes in the design. Read more about product testing methods in this article.

General Electronics Certification Steps

Although each country has its own consumer electronics certification and regulation rules, the general process is similar and usually appears as follows:

1. Determining the market. First off, companies must determine which market they want to enter and, consequently, which laws and regulations their product must comply with.

2. Studying the regulations. At this point, companies must determine what category of product their device falls into and which standards are applied. The easiest way to do it is to hire a consulting firm that will find the corresponding regulations. Remember that the same device can fall into several product types and, therefore, must comply with several standards.

It’s important that developers understand the parameters and functionality of the devices they are going to manufacture even before the design phase. An experienced company can design printed circuit boards and other components in compliance with the standards they expect to apply to.

3. Product design. Companies proceed to design the product with all the requirements in mind. Prototypes rarely pass the tests on the first try. Nevertheless, a device designed in accordance with the regulations will require fewer changes in the case of failure.

4. Testing. Depending on what type of certification companies want to obtain, they may be able to conduct the tests with their in-house equipment. Otherwise, developers will need to hire third-party laboratories to do it. In the case of failure, companies will have to make changes to the prototype and take the tests again.

5. Certification. Finally, if successful, companies will need to submit the required documentation to the appropriate authorities that will issue the corresponding certificate.

Tips on Consumer Electronics Certification

These tips will help companies make certifications faster, cheaper, and less complex.

1. Use pre-certified modules

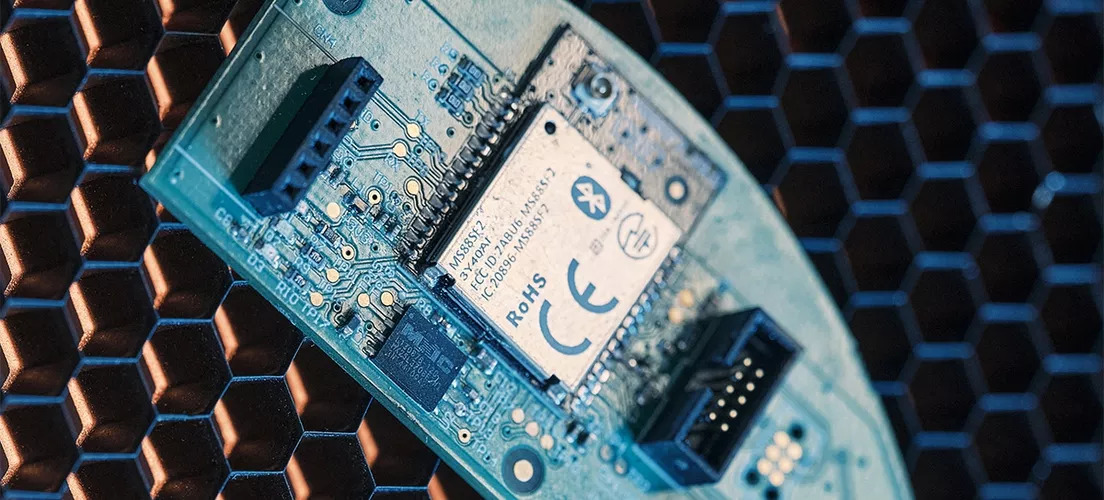

One of the ways to reduce the cost of certification and, in some cases, even avoid having to certify your product is to use modules that have already been certified. It is especially important for intentional radiators.

2. Perform internal consumer electronics testing during development

As mentioned before, it is crucial to understand what requirements your product will have to meet long before the final prototype is ready. Without internal tests, the first attempt to obtain the certificate can reveal the need for serious and costly design changes. Note that you don’t need official testing at this point.

3. Don’t apply for certifications before you’re ready for production

While being too late with testing can become a crucial mistake, applying for certifications too early can be just as harmful. Design for assembly can differ from your prototype a lot, so it is not a good idea to certify the device before you know how to manufacture it.

4. Do a sales test before certification

Most certifications are not mandatory if the company is going to manufacture only a few hundred products for a sales test. Therefore, there is no point in certifying the goods before making sure the product will sell (except for intentional radiators or devices that plug into AC outlets which will require certification anyway).

How we Manage Certification Challenges

As experts in custom hardware design, we take certification requirements into account when developing new devices. Although it is extremely difficult to pass tests at the first attempt, experienced developers should know how to fix issues without serious design changes. Here are a few examples of how we manage such challenges.

Case #1 (CE certification)

A customer asked Integra Sources to develop a USB Keylogger that could be hidden inside a keyboard and would record all keystrokes typed on it for the purposes of corporate data protection. The data would be kept on an internal NAND-flash and could be accessed by users with a specific key combination.

In order to reduce the radio interference, we decided to mount low-power components and additional filter capacitors on the USB interface, so that the interference wouldn’t spread through the USB. Special PCB tracking was also used to minimize the interference.

Despite these efforts, when the prototype was sent for CE certification, tests showed that the clock generator caused too much electromagnetic interference. To resolve this issue, the team protected this node with additional filter circuits, so we didn’t have to replace the clock generator with a more expensive one. We also repositioned certain components on the PCB.

After these changes, the device successfully passed the tests.

Case #2 (UL certification)

Another customer tasked us with developing a Wi-Fi-enabled control system that could be managed with a smartphone app. The system was supposed to be used in a humid environment, so safety was the number one priority and the client wanted to obtain UL certification for it.

At the research and development stage, the team decided that the best way to do it was to use pre-certified components. For example, it was decided to mount an FS12-2850-C2 power transformer in the PCB for a number of reasons.

First of all, as a hermetically sealed component, it was safely protected from moisture, making it an ideal solution for a system of this kind. Second, being a class 2 power transformer, FS12-2850-C2 features enhanced safety characteristics, namely low secondary voltage and low power that reduce electrical shock and power hazards, complying with the UL 5085-3 standard. Additionally, this component complies with RoHS3. It goes without saying that such features are crucial for a system designed to be used by people in a humid environment.

For the same reason, it was decided to use UL certified G5LE-1A-E DC5 and G5LE-1A4 DC5 power relays, as well as a number of pre-certified terminal blocks.

Case #3 (ESD testing)

Our job was to develop an Android application and firmware for a wearable ECG device (prototyped by the customer). The device was supposed to read biometric data via sensors and send them to the smartphone. However, the device malfunctioned during ESD tests.

The PCB used in the device was equipped with ESD diodes to provide protection from electrostatic discharges. The tests showed that the diodes allowed the device to survive ESD events; however, the discharges caused voltage fluctuations in the microcontroller power supply. The prototype would start working nominally only after a manual reset.

We proposed to use a watchdog timer that, after making changes to the firmware, would autonomously reset the microcontroller if it malfunctioned. In this case, the device would return to nominal mode quickly without interrupting the data flow from the sensors to the smartphone, and users wouldn’t notice any difference.

Unfortunately, we didn’t have the opportunity to test this solution as the customer decided not to prolong the contract.

Conclusion

Electronics certification is an important phase of product development associated with high costs and certain risks. Although “electrical certification” requirements differ from country to country, they are quite similar. Therefore, complying with one of them makes it easier to obtain another one.

For example, if you compare CE versus UL, you will discover that both of them cover safety. In this respect, CE can be considered as a UL equivalent in Europe. So, if your product complies with CE, UL testing won’t become a serious task. The same goes for other regulations, such as IC (Canada’s FCC equivalent), ACMA (Australia), Ofcom (UK), etc.

It is also important to understand the requirements at the design phase to make sure you won’t have to change the product design or manufacturing process too much. As a team of professionals, we know very well how to avoid such risks and how to develop electronics in compliance with different regulations. Contact us directly to discuss your project and the requirements to be taken into account.

View an infopraphic variant of the article here.

Share this article

Related

materials

5 Common US & EU Consumer Electronics Certifications in Infographics

Certifying a product requires time and money, which is why making a mistake here can lead manufacturers to serious financial...

LEARN MORE

LEARN MORE

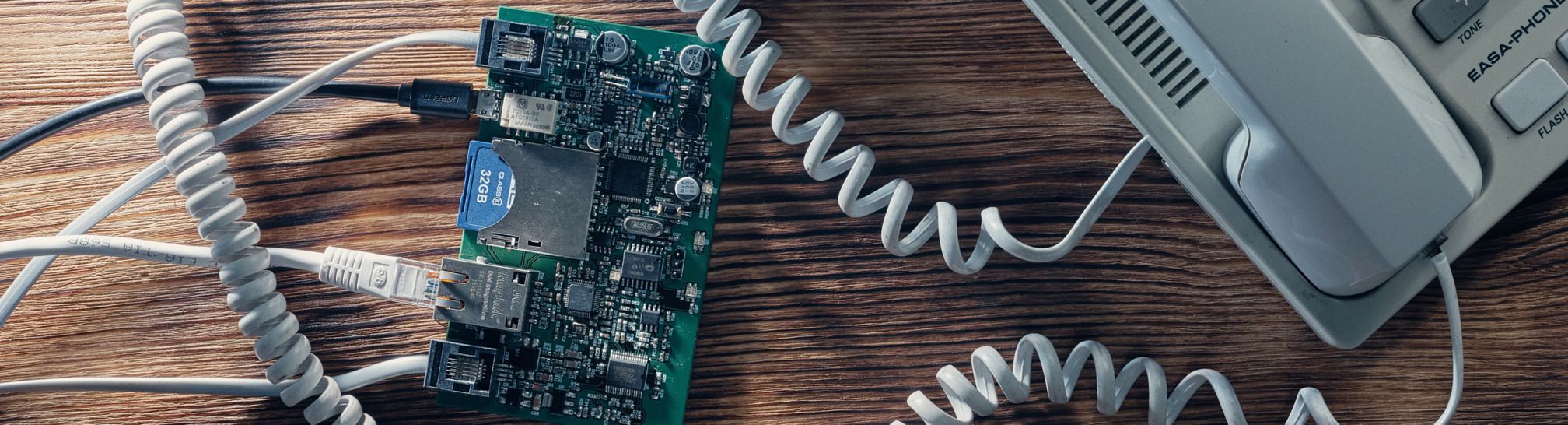

PBX Communications Device for Preventing Phone Fraud for Senior Citizens

We implemented a hardware design for a telecommunications device that gets installed in the homes of senior citizens and automatically...

LEARN MORE

LEARN MORE

PCB and Electronics Testing Before and During Manufacturing: Importance, and Methods of Implementation

Find out how PCB designers and manufacturers test circuit boards before and during production and why these actions are so...

LEARN MORE

LEARN MORE