This website uses cookies so that we can provide you with the best user experience possible. Cookie information is stored in your browser and performs functions such as recognising you when you return to our website and helping our team to understand which sections of the website you find most interesting and useful.

What Makes Electronics Prototyping so Important for Successful Product Development?

Timur Yuldashev

IT Writer, PhD in Philological Sciences

Andrey Solovev

Chief Technology Officer, PhD in Physics and Mathematics

Electronic product design and development begins with prototyping. Certain prototypes can be very similar to your final product, but they are always experimental in nature because electronics prototyping involves testing new concepts, ideas, and solutions. Although there’s a mishap risk, skipping this phase of electronic product development may lead to undesired expenditures. Businesses that don’t specialize in electronic hardware design often hire electronic prototype companies, such as Integra Sources. In this article, we will talk about the importance of prototyping and common prototyping phases.

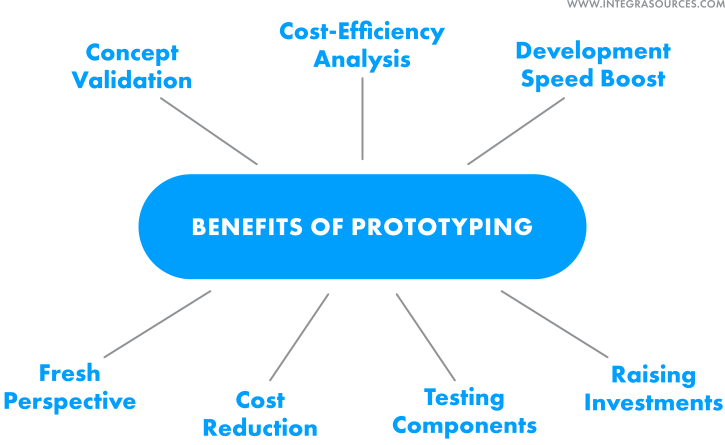

The Benefits of Prototyping for Electronics Development

Any product idea starts with a concept. It then gradually moves through the development process to the final product ready for mass production. Engineers often have to go in blind, so to say, as they can’t be sure which solutions will work and which won’t, and what components will show better performance or cost-efficiency. That’s why hardware prototyping plays an important role in designing electronics.

Electronics prototyping offers at least several benefits:

1. Concept validation

Often, when a customer asks us to develop a new electronic product, they only have a concept, i.e. an idea of how the device or system should work. But it isn’t always obvious whether an actual product can function the way they want. In this case, building a prototype can prove or falsify the idea.

2. Cost-efficiency analysis

For businesses, it’s not enough to prove that you can actually build hardware. Whether a consumer hardware product can become commercially successful depends on its cost-efficiency. Evaluating the cost of product development is possible even before the prototyping phase. But creating a prototype lets you further specify the costs. Evaluating manufacturing costs at the early development stages is difficult, but later prototype iterations can answer this question as well.

3. Prototyping speeds up development

On a small scale, it may seem that prototyping electronics wastes money and time and that this money could be spent on creating the final product right away. However, building test samples reduces the development time on a large scale: it reveals and helps eliminate the most crucial problems at early stages.

4. Fresh perspective

A new set of eyes will never hurt when you deal with software or electronic product development. Besides, a business can outsource these tasks to a third-party hardware design company because such firms have expertise in these fields.

So, if you want to design an electronic product but don’t know how to do it the right way, contact Integra Sources to benefit from our fresh vision and vast experience.

5. Cost reduction

First of all, the sooner you spot flaws in the design, the cheaper it is to fix them. Second, during the prototyping phase, engineers can find cheaper alternatives, which will reduce the cost of the final product. For example, when our team developed a Bluetooth musical pedal, we decided to use nRF51822 BLE SoC instead of the module we had planned to use initially (that was more expensive).

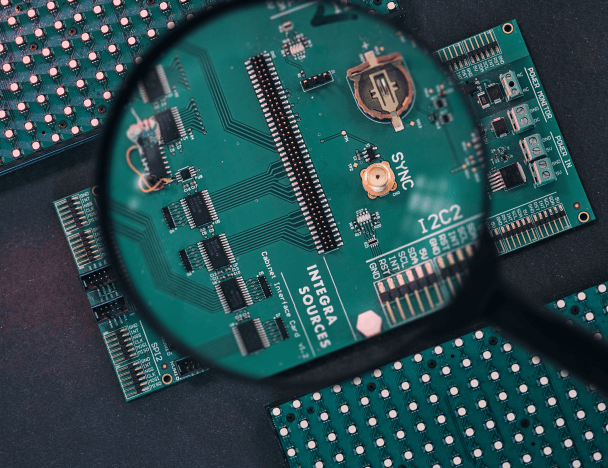

6. Testing components

At the prototyping phase, engineers can break down complex designs into simpler parts to test them individually. It helps us spot potential problems and find better solutions. If you’d like to know more about it, read our article on PCB and electronics testing.

7. Raising investment

Sometimes, companies prototype electronics hardware to show the device to potential investors and convince them to provide financial backing for further product development.

Developing hardware, electronics, firmware, and software requires highly trained specialists and vast experience. Therefore, it’s a common practice to ask for help from an outsourcing electronic prototyping company. Companies outsource not only development tasks but manufacturing as well. By 2027, the global electronic contract manufacturing and design market is forecast to reach $730.5 billion.

Despite all these benefits, prototyping carries certain risks as well.

Objective Risks of Electronics Prototyping

1. Your initial concept or idea may turn out to be unviable. Even if it is possible to create the device, its cost and complexity may make it economically unsound. On the other hand, one of the goals of prototyping is to answer these two questions.

2. Errors in the documentation for the components to be used in the prototypes. Such errors occasionally happen due to human factors. The problem can be solved by using alternative components. For example, our team tried to use Time-of-Flight sensors for two of our projects. But the sensors didn’t work the way described in the documentation, and we had to replace them with a different model.

3. Errors in electronic chips to be used in the prototypes. They can cause off-nominal work of the device. There are usually work-around options recommended by the chip manufacturers.

4. Certain components may become unavailable during prototyping or right before mass production. Such components may be withdrawn from production or become too expensive. Unfortunately, this happens very often in recent years, and there is little that can be done. In such cases, developers have to go back to prototyping to find a suitable replacement.

5. Manufacturing defects can be another risk, especially if they manifest themselves only after mass production was launched. In this case, the team will have to look for an alternative component and may even have to go back to the prototyping phase.

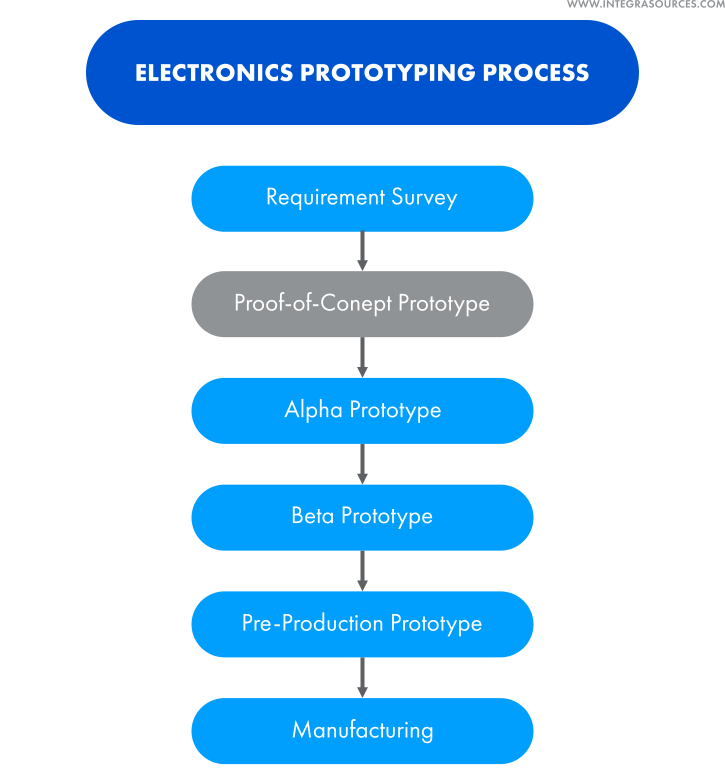

Electronics Prototyping Process and Types of Prototypes

Step 1. Requirement survey

A hardware development process always starts with a requirement survey. In our case, we contact customers to discuss the device’s features and functions, the size and shape of printed circuit boards, what power source should be used, what electronics certifications the product will have to comply with, and so on.

This stage is crucial for both electronic prototype companies and customers: the quality of the information received with the survey defines the quality of the further work. It is in the customer’s best interests to provide clear information on the key features of the future device or system. Clear technical requirements increase the chances of a swift and seamless development process. And that includes building a prototype that won’t need significant or costly modifications.

Step 2. Proof-of-Concept Prototype

At this phase, engineers may spot a number of potential problems that can be divided into critical and non-critical issues. The latter usually don’t require a lot of resources or time and can be solved quickly or at later phases. It is the critical issues that demand the team’s full attention. In this case, the process starts with creating a Proof-of-Concept prototype.

A POC’s only purpose is to prove that the concept is feasible, that it is technically possible to create a device with the functions specified by the customer. Therefore, at this phase, engineers disregard the project’s cost-effectiveness, size requirements, aesthetics, certification requirements, etc.

In electronics, the process starts with designing electrical schematics for the PCBs that will be used in the device. The team can use different types of prototyping methods here.

Virtual Prototyping

This method involves testing modules in virtual simulations. Here we don’t need to buy actual components and populate actual PCBs with them, so it’s cheap and simple. However, one can apply virtual prototyping only to relatively simple modules and nodes and only if there’s a mathematical or program simulation model. This method will not reveal all possible errors and issues but will allow engineers to spot some of them before they move on to build a real prototype.

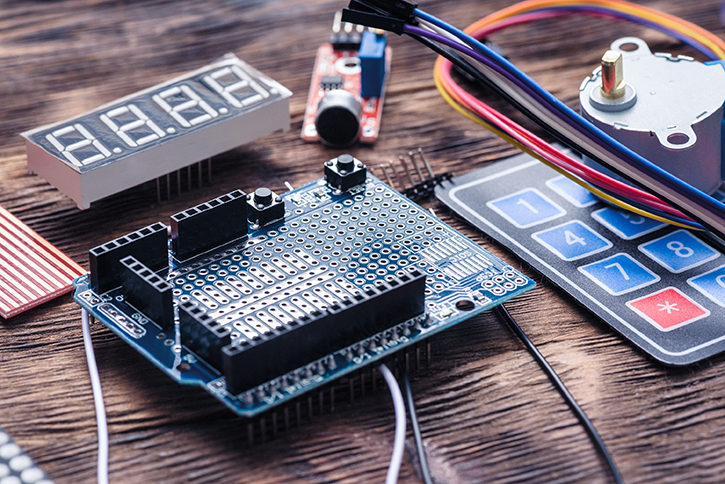

Using Development Kits and Electronics Prototyping Boards

If virtual prototyping is not an option (for example, due to the complexity of the modules), the team uses development and electronics prototyping kits to design printed circuit boards. Of course, prototypes assembled with development kits are far from perfection. They can be ugly, bulky, and often not efficient enough, but it shouldn’t scare you. At this point, our only goal is to make sure a device or module can work the way you want it to.

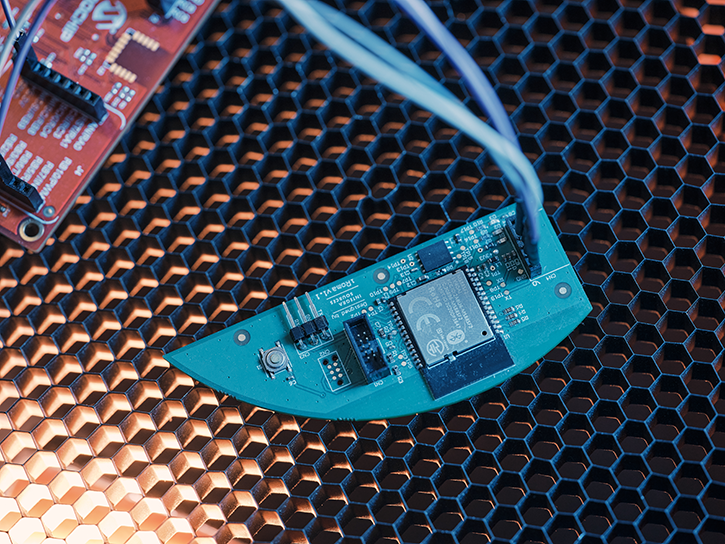

Designing custom PCBAs

Sometimes, neither modeling nor devkits can prove the concept or there’s no need to use these methods. In that case, engineers design custom PCBAs as POC prototypes. Although such modules are somewhat closer to the end product in terms of functionality, this solution is more expensive and takes more time.

Our engineers design the PCB layout with ECAD solutions. Once the layout is ready, we create a preliminary Bill of Materials (the list of the best-suiting components) and crosscheck the layout and BOM.

Then the PCB layout in Gerber format is sent to one of the factories we collaborate with, and they manufacture the PCB or PCBA. Before the pandemic, it took Chinese factories about 3 weeks to print and deliver custom-made circuit boards, but now it can take up to several months.

The number of iterations created at this phase depends on the complexity of the project, as well as the budget and time the customer can afford.

Step 3. Alpha Prototype

At this phase of electronic product design, we create an Alpha prototype, also called a minimum viable product (MVP). This device performs its key function; however, it may still lack certain secondary functions, features, or modules. At this point, they are considered insignificant and can be added later. Although an Alpha prototype resembles the final product, it doesn’t necessarily look neat and tidy. The team will have to make a lot of changes to the design. Nevertheless, the functionality of this iteration is enough to start working on its firmware.

As a rule, this phase requires one or two iterations. Also, at this point, we begin to run preliminary tests.

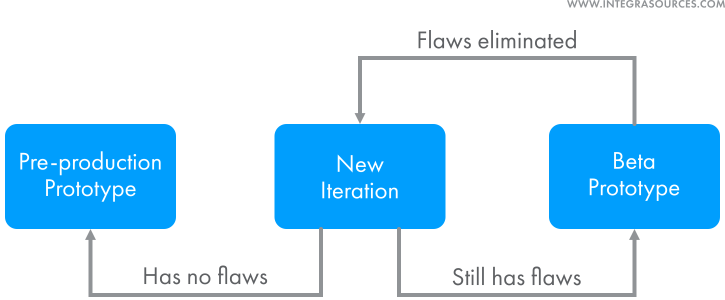

4. Beta Prototype

Ideally, at the next phase, we expect to build a fully-functional prototype that doesn’t have any flaws and is optimized for DFM (design for manufacturing). However, in practice, eliminating all of them is extremely difficult. Often, fixing one problem causes another one. So, a Beta is a prototype that is almost ready for mass production but still has flaws that must be eliminated.

Despite these flaws, at this point, the prototype is usually sent to certification so as not to waste time. By the time the test reports arrive, most problems will be fixed. Also, at this point, standard tests begin.

This phase requires a lot of experimentation, so the team often has to create more than one iteration (especially if the project is complex). Several copies are also built for tests and certification. Due to various uncertainties, it is difficult to estimate how much time the previous steps will take. Prototyping a Beta usually takes about 2-4 months.

5. Pre-Production Prototype

If we fail to eliminate all the flaws or these attempts cause new problems, the prototype is still regarded as a Beta and the process repeats. When the team successfully eliminates all the problems and the device works as intended (performing all the functions), we have a pre-production prototype. It is this iteration that goes for mass production. At this phase, the prototyping process is over.

These steps look like a strict plan of action. But in practice, it is only POC prototypes that we build intentionally. When the team moves on to the next phase, we can’t be sure what prototype we will create. With complicated projects, it’s hardly possible to avoid the Alpha phase. But with simple projects, you can actually build a Beta prototype as the first iteration.

Example of Electronics Prototyping

When a company hires an electronics prototyping company to develop a completely new product, it’s difficult to predict the exact course of action. However, sometimes projects happen to follow the steps described above. This example demonstrates a somewhat ideal electronic prototyping process.

An owner of an industrial design studio, who makes customizable keyboards among other things, asked us to prototype a capacitive keyboard. The client sent us one of the models available on the market as a reference. The team was supposed to create a similar device.

Unlike standard keyboards, a capacitive keyboard uses capacitors placed under each key. In this case, when pressed, the key would push on a cone-shaped spring. The spring, in turn, would increase the mutual capacitance of the capacitor pads located under the key. Our objective was to prototype a matrix circuit that would be able to poll all the buttons, detect the slightest changes in the capacitance, and, thus, register keystrokes. Another objective was to make sure the poll time would not exceed 1 msec.

Phase 1: Proof-of-Concept

In order not to waste the customer’s money, the team decided to start the hardware design process with a virtual model and solve the poll time problem first. We used LTSpice to create a virtual model of the circuit board.

The idea was to consecutively apply short pulse bursts to each row of the keyboard matrix and pick up the signals from the matrix columns. Then the signal would be fed to an operational amplifier to make it more distinguishable. Since even unpressed buttons would still transmit a weak signal, the team decided to add a comparator to the scheme. The comparator would cut off such impulses.

The model allowed us to understand what amplification factor was necessary and what components were suitable for the device.

Phase 2: Alpha Prototype

After modeling the electronic hardware design and simulating its work, our team assembled the first prototype with a development kit. At this point, we needed to specify the amplification factor and the comparison level. We also developed simple firmware that was able to detect simultaneous key presses.

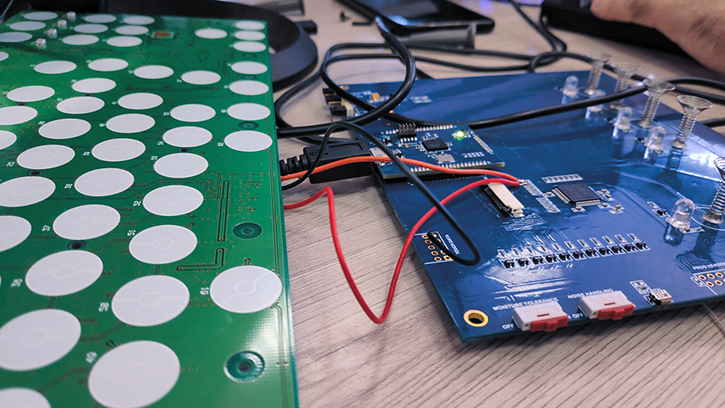

Phase 3: Beta Prototype

After that, our circuit designers created the layout for the PCB and ordered the PCBA from our partner factory. When the prototype arrived, the programmer finished the firmware and the engineers ran a few tests. The form-factor suggested by the client was identical to the one of the original keyboard. So, we were able to install the circuit board into the reference keyboard and test it.

The tests showed that the inverting operational amplifier circuit provided insufficient amplification. So, we had to change it to non-inverting, which required rerouting some tracks. After these changes, the prototype performed as intended, so it was sent to the customer for approval.

Phase 4: Pre-Production Prototype

The client was satisfied with the prototype’s performance, and the team ordered a new PCBA (with the changes made during the previous iteration). The circuit board that arrived became the final prototype suitable for production.

Common Traps of Electronics Prototyping

Whether you hire an outsourcing company or prototype devices with your own resources, there are certain risks that can result in spending too much money and time on this development phase.

1. Providing insufficient information

If a company doesn’t deal with product development directly, its executives may underestimate the importance of certain requirements. This may eventually lead to serious problems at later development phases. For example, if the company doesn’t mention that the product will need to be certified, the development team may have to start the whole process from the beginning when the company updates the list of requirements.

2. Setting no clear goal

Electronics hardware prototyping is a lengthy and costly process, so starting it with no clear goal is a dangerous mistake. When making a decision, companies should understand exactly what they want to achieve. For example, for a completely new idea or concept, the goal could be to prove that a device like this can be created. Without a clear purpose, tests and experiments can go on for months and lead to nowhere.

3. Getting carried away

When developing a new electronic product, it’s easy to get carried away. An outsourcing company that designs custom electronics can be kept in line by the customer (the budget and deadlines they set). But there’s nobody to hold back the customer.

This can lead to spending time and money on new functions and features that were not initially planned. As a result, you get a never-ending iteration cycle that goes way over your initial budget and deadlines. Additionally, by getting carried away, companies may miss the moment when it’s time to estimate the production costs. In the worst-case scenario, the developers will have to remove all those new features and functions that consumed so much time and effort.

4. Focusing on what works

A prototype is not meant to function properly. If the first iteration of your product has flaws, it’s absolutely normal. This is what prototypes are made for – to spot problems and find ways to fix them. So, instead of working on what’s working properly, companies should focus on what isn’t.

5. Stopping too soon

Another common risk is to mistake your prototype for the final product. For example, Beta iterations should be suitable for mass production. However, they still have flaws that make high-volume production either too expensive or impossible at all. Putting such prototypes in production will result in additional and unnecessary expenditures.

Conclusion

Prototyping plays a major role in electronics product design. This development phase lets you answer a set of key questions, such as whether a product can or cannot be manufactured and how much it will cost. Electronics prototyping can help you estimate the economic viability of a project at early stages and find the most cost-efficient solutions to any challenges that arise in the process.

Industrial and consumer electronics design requires expertise in both electronics engineering and programming. When hiring new employees for designing electronics is not an option, delegating this task to an outsourcing company is a good alternative.

Developing a product from scratch usually takes several months. But complex projects can take a few years to complete. It depends on budget limitations and whether the team has experience with similar projects. As for the budget, the total cost can vary from a few thousand dollars to dozens of thousand dollars.

When hiring a development team, you also sign a non-disclosure agreement that protects your intellectual property rights.

Our team has vast experience in prototyping industrial and consumer electronics, robotics, IoT, AI, and machine learning devices and power electronics. In our portfolio, you will find plenty of projects that were started as a concept. Now, they have reached the production phase. We also understand how to administer budgets effectively and meet deadlines at the same time. If you need to estimate the potential of a new project, build a hardware prototype, or develop a device from the ground up, contact us directly to discuss how we can help you.

You can also check the infographic variant of our post about electronic prototyping.

Share this article

Related

materials

Autonomous Robotic Lawn Mower

The robot has an autonomous navigation system with sensors and intelligent algorithms. We provided both hardware design to software development.

LEARN MORE

LEARN MORE

PCB and Electronics Testing Before and During Manufacturing: Importance, and Methods of Implementation

Find out how PCB designers and manufacturers test circuit boards before and during production and why these actions are so...

LEARN MORE

LEARN MORE

PCB and Electronic Testing Methods in Infographics

Discover various PCB testing methods needed to ensure the quality and functionality of electronic devices.

LEARN MORE

LEARN MORE